March 15, 2012 report

Cost-cutting drives solar cell process at Twin Creeks

(������ƵOrg.com) -- A San Jose, California, startup company, Twin Creeks Technologies, says it has figured out a way to substantially cut the cost of making silicon solar cells. The company’s technology reduces both the amount of silicon needed and the cost of the manufacturing equipment. The company can produce solar cells for about 40 cents per watt, half the present-day price of the cheapest cells at 80 cents.

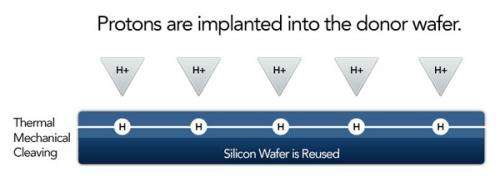

The Twin Creeks approach differs in a process that reduces the use of wire saws and related equipment as well as makes thinner wafers. Its production system for making the ultra-thin wafers is called “Hyperion.” The technology is described at Twin Creeks as “Proton Induced Exfoliation" (PIE). Crystalline silicon wafers, accounting for the bulk of solar cells, conventionally are made in a process of cutting blocks or cylinders of silicon into 200-micrometer-thick wafers. According to the company, the key to Hyperion is “thinness.”

The Twin Creeks business plan is to sell the manufacturing equipment, rather than produce solar cells itself. The selling point is that, with thin wafers, manufacturers can profitably produce solar cells and other devices below today’s best-in-class cost structure, according to the company. Twin Creeks estimates that Hyperion will permit manufacturers to produce solar cells for under 40 cents a watt in commercial-scale volume production facilities, with prices going down over time.

In the bigger picture, the company’s vision is to make a real difference in the costs of generating solar power. Silicon, notes Twin Creeks, is still the most expensive component of a finished solar module and the single highest expense when it comes to generating solar power.

The startup’s goal is, according to the company’s website, “to disruptively reduce the cost of solar energy to achieve grid parity.” The company says its Hyperion system can produce ultra-thin wafers less than one-tenth the thickness of conventional silicon solar wafers.

“Hyperion can fundamentally change the cost structure of many other industries that rely on high-cost, single-crystal wafers for their devices.”

To prove its points, the company has demonstrated the technology at a 25-megawatt-per-year solar-cell factory that it built in Senatobia, Mississippi. The solar factory was built through loans from the state of Mississippi, venture capital, and other sources. The plant is being used as a site where Twin Creeks and its customers can fine-tune processes for generating ultra-thin solar modules and wafers with Hyperion. The plant, though currently capable of producing 25 megawatts of solar cells a year, will be expanded to a capability of 100 megawatts, according to plans.

More information:

© 2011 ������ƵOrg.com