March 24, 2017 report

Electrodeposition and annealing used to allow for adjusting hardness in nanograined metals

Bob Yirka

news contributor

(������Ƶ)—A team of researchers from China and France have adjusted the hardness of nanograined metals by applying electrodeposition and annealing. In their paper published in the journal Science, the team describes their technique and suggests some applications they believe could benefit from such metal treatments.

Normal metals tend to become harder as their grain size grows smaller (as described by the Hall–Petch relationship), but the same is not always true for certain nanograined metals—they actually grow softer. In normal metals, smaller grain size increases strength because of pileups between grains—the pileups work against dislocation, making it more difficult for the metal to be bent or to break it. But when grain size is at the nanoscale (from 10 to 30 nm in size), things change, because instead of pileups, grains can sometimes simply move when stressed. This means some nanograined metals can actually grow softer as more migration occurs. In this new effort, the researchers discovered a way to manipulate grain migration that allowed them to adjust the hardness of a metal.

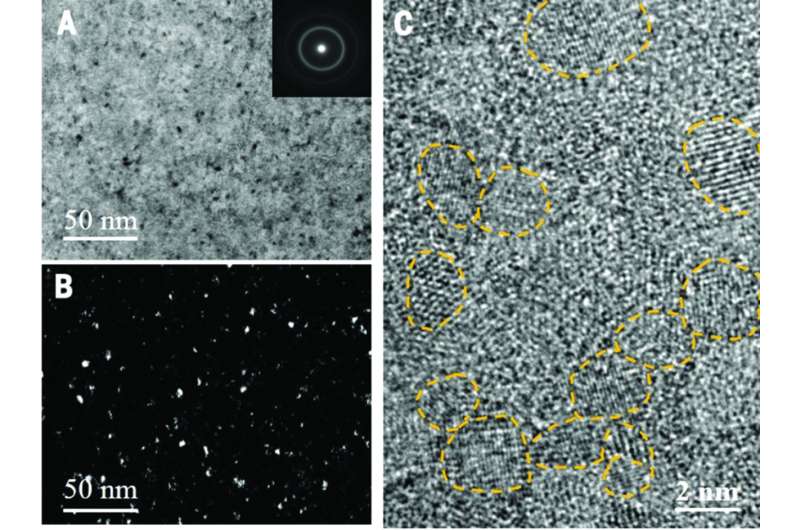

The new technique involved using electrodeposition (using electricity to reduce dissolved metals to form coatings) and annealing (heating then allowing to cool slowly) a sample of nickel and molybdenum. Doing so pushed the molybdenum into the boundaries between nickel grains, which prevented the nickel grains from migrating under stress. The result was a nickel metal made with nanograins that was much stronger than if it had been made by conventional means.

The researchers report that the smaller the grains, the better their technique worked, which allowed them to create several synthesized versions of nanograined metals that were extraordinarily hard—in some cases as hard as ceramics. They believe their technique could lead to the development of new metals with unprecedented hardness or coatings that could protect other softer or more sensitive materials. They note that their technique allows for the creation of metals with widely varying degrees of hardness by varying grain size and the degree to which electrodeposition is used versus annealing and whether it is synthesized at all, which gives manufactures more options when designing products.

Written for you by our author —this article is the result of careful human work. We rely on readers like you to keep independent science journalism alive. If this reporting matters to you, please consider a (especially monthly). You'll get an ad-free account as a thank-you.

More information: J. Hu et al. Grain boundary stability governs hardening and softening in extremely fine nanograined metals, Science (2017).

Abstract

Conventional metals become harder with decreasing grain sizes, following the classical Hall-Petch relationship. However, this relationship fails and softening occurs at some grain sizes in the nanometer regime for some alloys. In this study, we discovered that plastic deformation mechanism of extremely fine nanograined metals and their hardness are adjustable through tailoring grain boundary (GB) stability. The electrodeposited nanograined nickel-molybdenum (Ni–Mo) samples become softened for grain sizes below 10 nanometers because of GB-mediated processes. With GB stabilization through relaxation and Mo segregation, ultrahigh hardness is achieved in the nanograined samples with a plastic deformation mechanism dominated by generation of extended partial dislocations. Grain boundary stability provides an alternative dimension, in addition to grain size, for producing novel nanograined metals with extraordinary properties.

Journal information: Science

© 2017 ������Ƶ