Creating stronger and more ductile microlattice materials with reduced unit sizes

Projection micro stereolithography (PμSL) has emerged as a powerful three-dimensional (3D) printing technique for manufacturing polymer structures with micron-scale high resolution at high printing speed, which enables the production of customized 3D microlattices with feature sizes down to several microns. However, the mechanical properties of as-printed polymers were not systemically studied at the relevant length scales, especially when the feature sizes step into micron/sub-micron level, limiting its reliable performance prediction in micro/nanolattice and other metamaterial applications.

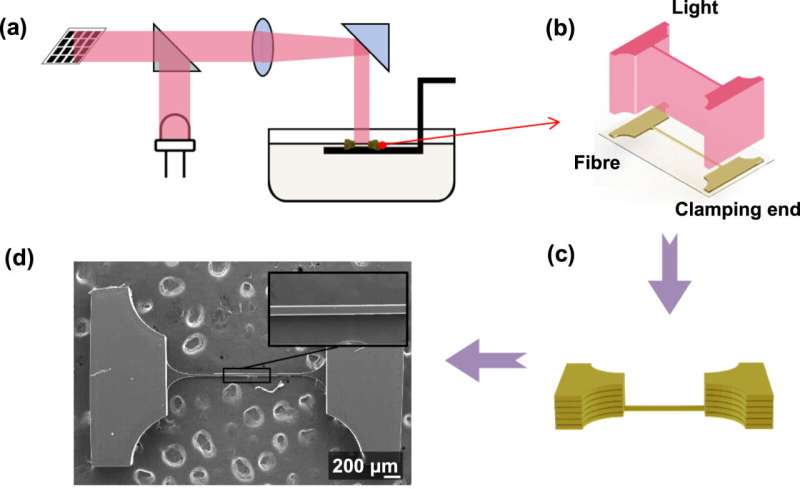

Based on self-developed in situ micro-mechanical platform, Prof. Yang Lu from City University of Hong Kong demonstrates that projection micro-stereolithography (PμSL)-printed microfibers could become stronger and significantly more ductile with reduced size ranging from 20 μm to 60 μm, showing an obvious size-dependent mechanical behavior, in which the size decreases to 20 μm with a fracture strain up to ~100% and fracture strength up to ~100 MPa.

Such size effect enables the tailoring of the material strength and stiffness of PμSL-printed microlattices over a broad range, allowing to fabricate the microlattice metamaterials with desired/tunable mechanical properties for various structural and functional applications.

Incorporating the size effect of the PμSL printed polymer allows us to obtain microlattice with different mechanical properties yet the same topography and relative density. The modulus of the microlattice with 20 μm is measured to be ~87 MPa about twice compared with that of the lattice with struts diameter of 60 μm (~43 MPa). After the lattices were yielded, the stress of the lattice with 20 μm struts increased with the strain. This may be attributed to the strain hardening phase of the micro-sized struts. While the lattice with a diameter of 60 μm shows typical stress curves of brittle materials.

This result reminds us to consider the size of the polymer when designing microlattice metamaterials. Such size-dependent mechanical behavior of PμSL-printed acrylate-based resin structures enables the tailoring of the material strength and stiffness of microlattice units over a wide range, enabling the rational fabrication of microlattice scaffolds with desired/programmable mechanical properties for the development of novel micro/nano-lattice mechanical metamaterials.

"Nowadays, vat photopolymerization 3D printing technologies, such as PµSL, can provide an excellent combination of ultrahigh printing resolution and large printing size, paving the paths for geometrically complex components with well-defined hierarchical structures for structural and functional metamaterials," explains Professor Lu Yang in the Department of Mechanical Engineering, who led this research.

"A deep understanding of the mechanical properties of PμSL-printed polymer at small length scales will accelerate the development of advanced mechanical metamaterials such as micro/nanolattice materials with unprecedent performance. Size-dependent mechanical properties of materials has been always the central focus of my group's research. It also inspires us to pay more attention to utilize such size effects for designing advanced mechanical metamaterials with critical features steps into micro/nanoscales."

The research was published in the International Journal of Extreme Manufacturing.

More information: Wenqiang Zhang et al, Tailoring mechanical properties of PμSL 3D-printed structures via size effect, International Journal of Extreme Manufacturing (2022).

Provided by International Journal of Extreme Manufacturing